The manufacturing sector is the third-largest in Canada. With over 1.6 million workers, it has the second-highest number of accident claims resulting in lost work time.

Most of these events were related to:

- Slips, trips, and falls

- Machine and equipment hazards

- Contact with hazardous materials

Top five most common hazards in manufacturing

Slips, trips, and falls

Accidents resulting from wet floors, cluttered walkways, or insufficient lighting can lead to injuries.

Machine hazards

Potential dangers like entanglement, crushing, or dismemberment are all potential risks when operating machinery.

Chemical hazards

Risks posed by exposure to toxic, flammable, or corrosive materials are hazardous to workers’ health.

Fire hazards

Risks from flammable substances and faulty electrical equipment can lead to fires and explosions.

Noise

Health risks from prolonged exposure to high noise levels can cause hearing damage.

Manufacturing accident statistics

This sector is 2.2 percent more dangerous than it was in 2022, due to an increase in mental stress, serious injuries, and fatalities.

In an average year, tens of thousands of manufacturing workers suffer injuries; recent data show on the order of 30,000 or more lost-time claims per year in this sector.

Be proactive—prevent workplace injuries!

Proactive safety starts with the hierarchy of controls. If hazards can’t be eliminated, engineering controls are the first level of protection. If those aren’t practical, utilize administrative controls like training, SOPs, and incident reporting. Finally, while PPE is essential, it provides the lowest level of protection, and should be used alongside other higher-level controls.

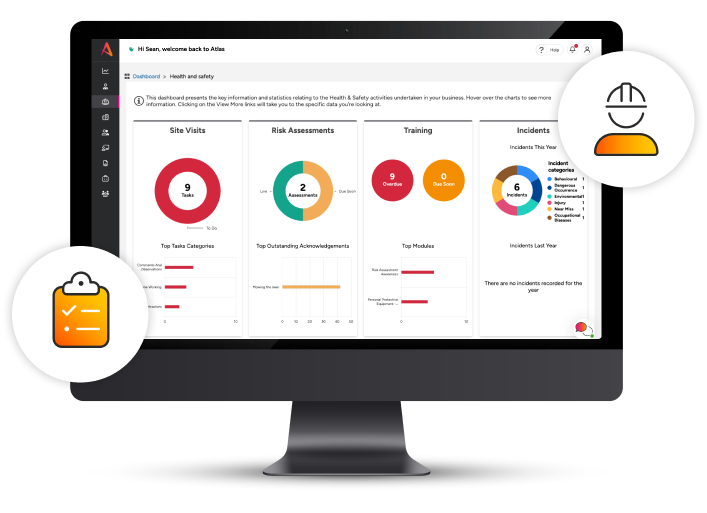

Risk assessments

Risk assessments allow for the creation and implementation of targeted control measures to reduce workplace and operational risks. Conducting thorough risk assessments helps manufacturing companies stay compliant with safety legislation.

Incident reporting

Incident reporting plays a crucial role in enabling construction companies to recognize patterns and address root causes, paving the way for effective strategies that help prevent similar accidents.

Safe Operating Procedures

Safe operating procedures (SOPs) provide detailed instructions that guide workers in executing their duties while minimizing risks. These procedures standardize best practices, ensuring that every worker is aware of the correct methods for completing tasks safely.

Training and education

Safety training provides workers with curated, professional-grade content that covers the latest safety protocols, best practices, and emergency procedures. Along with training, adding informal coaching and short toolbox or pre-shift safety talks helps cultivate a safety-first culture in the workplace.

Connect with one of our health and safety experts today

With innovative technology, expert guidance, immersive online training, incident reporting tools, and risk assessment software, our award-winning Health & Safety software and support help manufacturing companies across Canada build stronger, more effective safety programs.